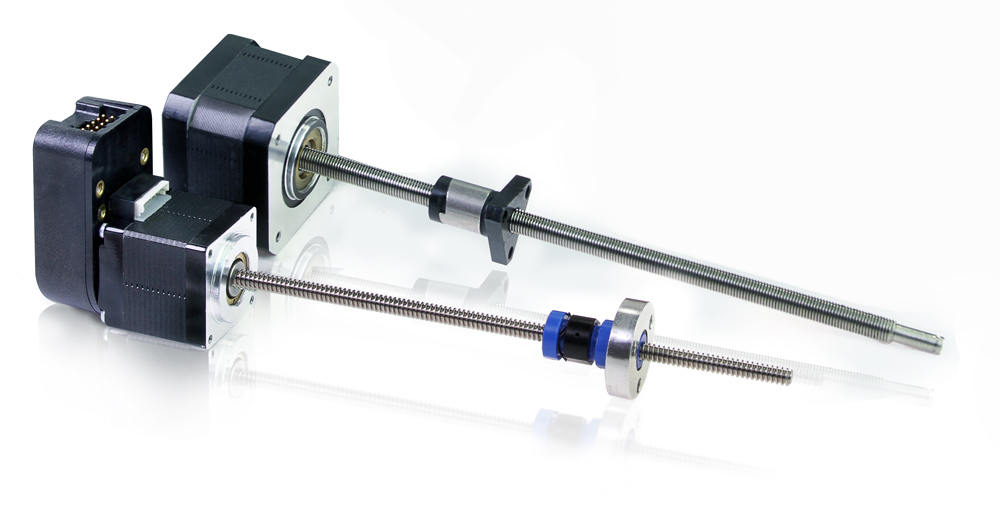

Rapid Prototype Configurator is a tool to help you configure and receive a prototype linear actuator so you can start your evaluations quickly, easily, and with confidence.

- Answer four simple questions about your needs

- Select from thousands of potential combinations for fast delivery

- Start testing and configuring your system quickly

- Decide on your final motor requirements

- Nail down production unit specifications

Fully Configured Prototype, In-hand, ASAP.

Linear Actuator Rapid Prototyping Configurator let’s you configure a linear actuator that will deliver the right amount of force at the right speed with the right modification for your application.

We’ve narrowed down a selection of products and modifications to satisfy majority of requests, while ensuring fast production time. All available parts are stocked at our facility in Northern California where we complete the prototype assembly.

Bring Your New Products To Market Faster.

Speed to market is crucial. We’ve developed this tool to aid Design Engineers with new product development and iteration. This tool will help you configure and receive your linear prototypes quickly, so you can start testing your new products or assemblies as quickly as possible.

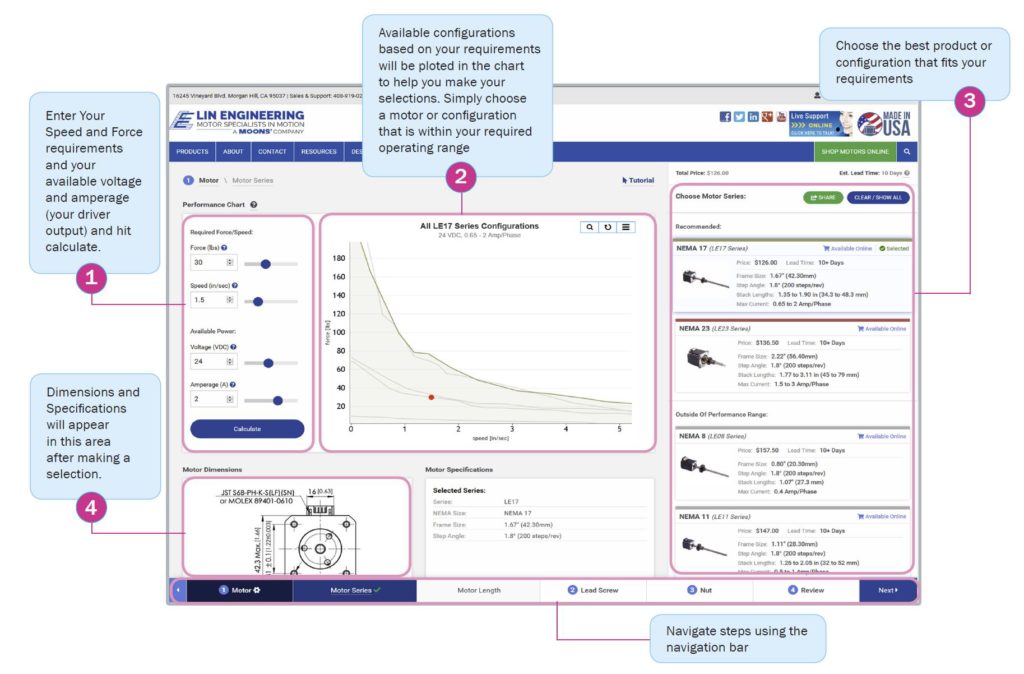

How Does It Works?

Answer four basic questions:

- How much force are you trying to push?

- At what speed?

- What is your available voltage

- What is your available amperage

From there, the software will calculate performance curves for each available combination, and recommend motor series, stack lengths, and lead screw combinations that will work within your project. All you have to do is make a selection that will work for you.

Need More Options and Modifications?

We are capable of far more than what you see in the Rapid Prototyping Configurator. We can provide additional lead screws and nuts; modify the leads and connectors of the motor; make further modifications to the housings for simplified installation; create custom windings to increase force at specific speeds or to reduce resonance at specific speeds; make further modifications to the leads screws; or mount additional hardware such as encoders. Just tell us about your application needs and we’ll provide the most optimal solution.

Nail Down Final Configuration.

We will work with your team throughout the development process of your product to ensure correct optimization and fit. We’ll create a part number that is assigned to you and start delivering required volume on schedule to meet your production demands.

We’ll Grow With Your Needs.

All of our engineering and prototyping is done at our Northern California facility, while our production options are based on volume and customization levels—assembly can occur in Northern California or overseas. Most importantly, Lin Engineering is capable of meeting your volume requirements, whatever they might be!

Give It A Try.