R525P

MICROSTEPPING CLOSED-LOOP DRIVER

- Operates from +12 to 48 VDC

- Software selectable run currents from 0.1 to 5.0 Amp Peak

- Software selectable hold currents from 0 to 5.0 Amp Peak (in 0.05 Amp increments)

- Step Resolutions from Full step to 256x Microstepping

- Communicating using RS485 and USB

- Operates in both Open loop and Closed loop modes

- Programmable analog input to change velocity and position.

- Programmable digital output for feedback.

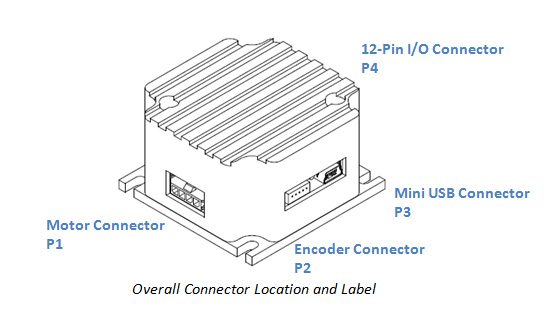

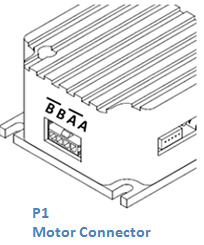

P1 MOTOR CONNECTOR PIN-OUTS

| PIN | FUNCTION | COLOR |

|---|---|---|

| 1 | Motor Phase A | RED |

| 2 | Motor Phase A- | BLUE |

| 3 | Motor Phase B | GREEN |

| 4 | Motor Phase B- | BLACK |

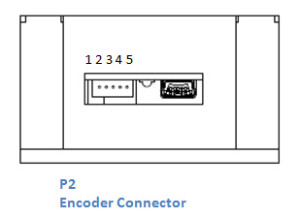

P2 ENCODER CONNECTOR PIN-OUTS

| PIN | FUNCTION |

|---|---|

| 1 | Channel B |

| 2 | 5V Input |

| 3 | Channel A |

| 4 | Index |

| 5 | Ground |

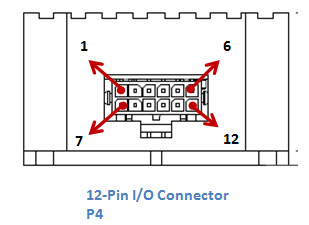

P4 I/O CONNECTOR PIN-OUTS

| PIN | FUNCTION | COLOR | DESCRIPTION |

|---|---|---|---|

| 1 | +5V out | Red/White | 5 VDC out |

| 2 | Opto COM | Yellow | This is a 5VDC input in order to optically isolate the logic signals (step, direction, disable pins). If no isolation is required, you can connect this pin to Pin 1, the 5VDC output. |

| 3 | Disable pin | Blue | Enable/Disable pin. When pin is low, or touching Pin 12 Ground, the driver is disabled. If left alone (high), driver is enabled |

| 4 | RS485/A | Black/White | Communication line for RS485 connection. Used for dasiy chaining multiple units |

| 5 | Ground | Green/White | Power Supply Ground |

| 6 | POWER+VE | Red | Motor Power Supply Voltage, +12 to 48VDC |

| 7 | Direction | Orange | Direction input. Default connection will rotate the motor CCW. If this input is low, or touching Pin 12 Ground, rotation will be CW. |

| 8 | Analog input | White | This input can take a potentiometer |

| 9 | Step input | Blue/White | Step pulse input. The step clock input will receive a clock pulse input (TTL squarewave signal, 0 to 5VDC), where one pulse will move the motor one step |

| 10 | RS485/B | Brown | Communication line for RS485 connection. Used for dasiy chaining multiple units |

| 11 | Output | Black | Via the GUI, user can choose to disable the unit, change motor direction, close upon fault, toggle when index is detected on the encoder, close when motor is stalled, moving or holding |

| 12 | Ground | Green | Signal ground, also known as digital ground |

- OPERATES FROM +12 to 48 VDC

- DRIVE CURRENTS (per phase): 0.1 to 5.0 Amps Peak

- ISOLATED INPUTS:Step,Clock, Direction, and disable

- STEP FREQUENCY (Max): 1 MHz

- STEPS PER REVOLUTION (1.8° MOTOR): 200, 400, 800, 1600, 2000, 3200, 5000, 6400, 10000, 12800, 25000, 25600, 50000, 51200

- MICROSTEP RESOLUTIONS (1.8° MOTOR): Full step, 2X, 4X, 5X, 8X, 10X, 16X, 25X, 32X, 50X, 64X,125, 128X, 250X, 256X

- OPERATING TEMPERATURE: Heatsink maximum temp 85°C

documentation

Accessories

-

RS485 to RS232 Designer’s Kit Converter Card Kit

Features & Benefits

Features & Benefits- Allows user to connect the R256, R356, Silverpak 17C/CE, 23C/CE, and 34D motors to a PC via a standard serial port

- RoHS compliant

- RS485 to RS232 Converter Card

-

USB485 Converter Card

Features & Benefits

Features & Benefits- Allows the user to connect their RS485 device to a PC via a standard USB port.

- UART I/F Supports 7 / 8 Bit Data, 1 / 2 Stop Bits and Odd/Even/Mark/Space/No Parity

- Data rate 300 => 250K Baud

Drivers & Controllers

-

R208 MICROSTEPPING DRIVER

Features & Benefits

Features & Benefits- Bipolar Step Motor Driver

- Operates from +12 to 24 VDC

- Phase current ranges from 0.35 to 2.0 Amps Peak

-

R256 SINGLE AXIS CONTROLLER+DRIVER

Features & Benefits

Features & Benefits- Input Voltage of +12 to 40 VDC

- Phase Current Ranges from 0.2 to 2.0 Amps Peak

- Full step, 1/2, 1/4, 1/8, 1/16, 1/32, 1/64, 1/128, 1/256

-

R356 Single Axis Controller+Driver

Features & Benefits

Features & Benefits- Input Voltage of +12 to 40 VDC

- Phase Current Ranges from 0.2 to 3.0 Amps Peak

- Full step, 1/2, 1/4, 1/8, 1/16, 1/32, 1/64, 1/128, 1/256

-

R701 MICROSTEPPING DRIVER

Features & Benefits

Features & Benefits- 10 microstepping driver

- Optically isolated Step, Direction, and Disable/Enable inputs

- Automatic Current Reduction

Stepper Motors

-

4118 Series High Torque Stepper Motor

Features & Benefits

Features & Benefits- More torque than standard NEMA 17 stepper motors

- Custom wound for high speed or low speed applications

- Up to 115 oz-in (0.81 N-m) Holding Torque

-

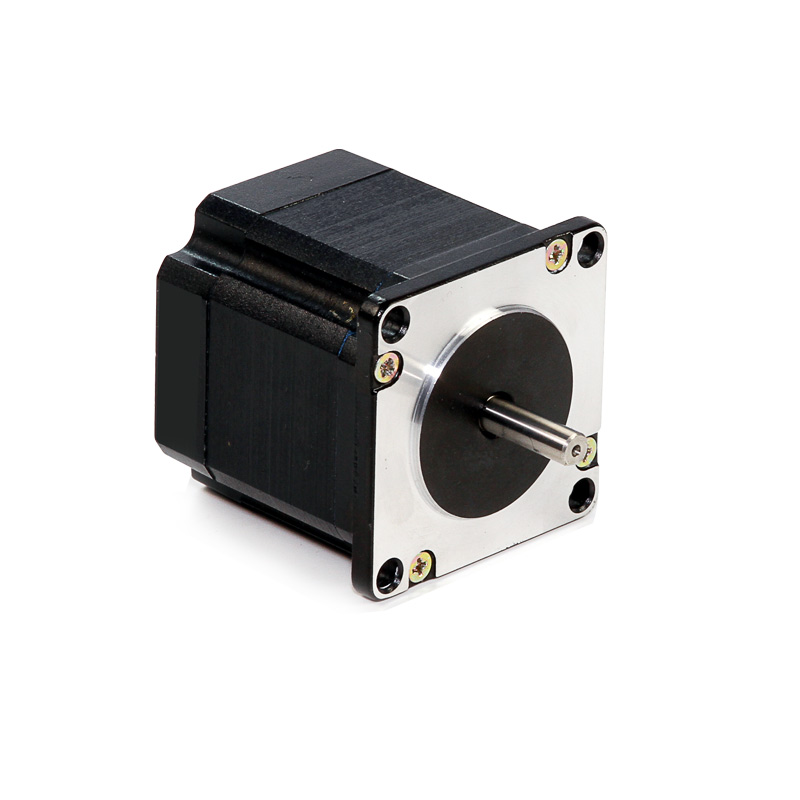

5718 Series High Torque Stepper Motor

Features & Benefits

Features & Benefits- High Torque

- Cost effective

- Up to 305 oz-in (2.16 N-m) Holding Torque