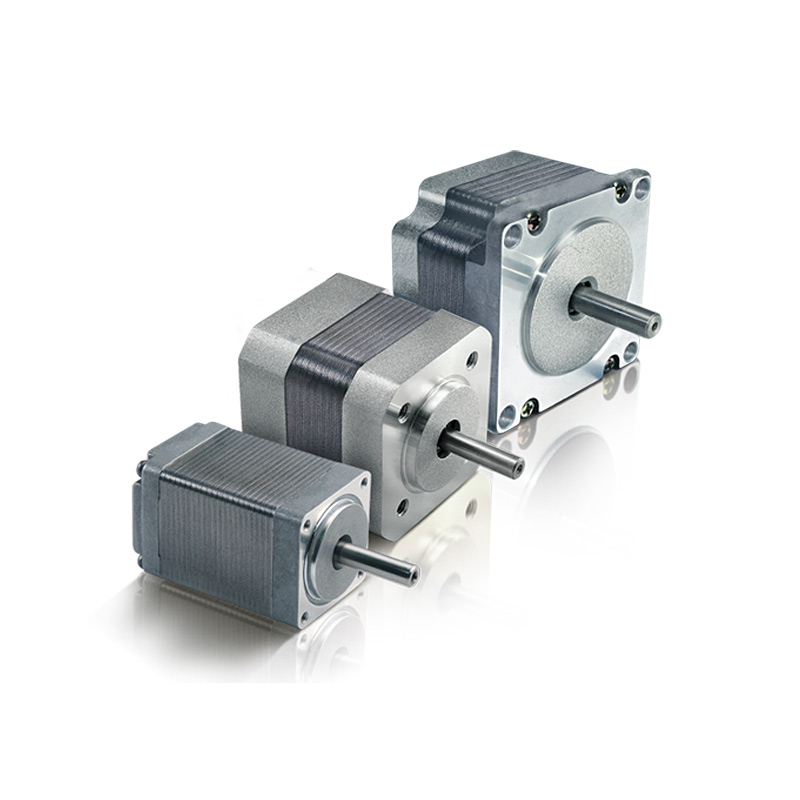

Vacuum Rated Motor

IP RATINGS | IPX7 | LAB RATED | TEMPERATURE RATED|

-

While our standard line of stepper motors are known for their durability, some applications require a bit more than standard protection. The vacuum rated stepper motors from Lin Engineering are manufactured to operate in cleanroom environments where outgassing needs to be avoided. Please see below for more information and request a quote to get started!

Products

While our standard line of stepper motors are known for their durability, some applications require a bit more than standard protection. The vacuum rated stepper motors from Lin Engineering are manufactured to operate in cleanroom environments where outgassing needs to be avoided. Please see below for more information .

Features

• Vacuum Ratings up to 10-7 Torr at 125°C

• Special windings and teflon leads utilized

Popular Applications

The following motors are available as vacuum rated:

A customized cleaning process combined with a vacuum bake-out is used to encourage outgassing of residual contaminants. Vacuum lubricated Bearings are rated from -80°C to 204°C which translates to a maximum motor external body temperature of 125°C. Prior to being shipped, all motors are wrapped in a clean room cloth and sealed air-tight. Special handling and care must be taken once package has been opened. This also passes Class 10 clean room requirements.

Depending on your chamber size and vacuum pump rate, these motors should be able to reach up to 10-7 Torr at 125°C. Motors were tested in a chamber size of 1 Liter at a pressure rate of 1 mL/mm.

HOW CLEAN IS CLEAN?

Evaluation

Measurement of Outgases

Test Setup

Test Process

A test motor was put into a positive flow chamber (N2 Gas flow 1mm/1min) and we measured the outgassing levels over 72 hours at a temperature of 125°C

The measurements taken were:

• Total Mass Loss Percentage (%TML)

• Total Mass Loss (ug/motor)

For more details, ask Lin Engineering

Test Result

| SAMPLE | % TOTAL MASS LOSS (TML) | MASS LOSS (ug/motor) |

|---|---|---|

| Competitor | 0.030 | 105,000 |

| Lin Engineering | 0.008 | 29,000 |

Definitions

%TML: Percentage of Total Mass Loss. The larger the

percentage, the “contaminated” the specimen is.

Mass Loss (ug/motor): The weight of the mass that was evaporated into the chamber from the specimen. The larger the number, the “contaminated” the specimen is.