- Frame Size: NEMA 17

- |

- Step Angle: 1.8°

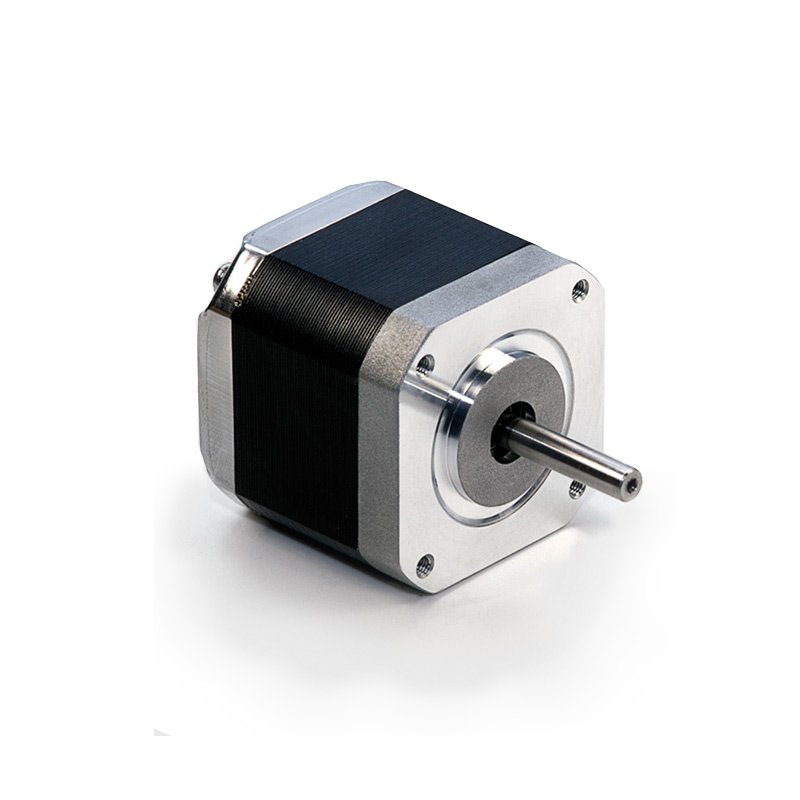

4418 Series

Xtreme Torque Stepper Motor

- Up to 35% more torque than standard NEMA 17 stepper motors

- Custom wound for high speed or low speed applications

- Up to 100 oz-in (0.71 N-m) Holding Torque

Standard Motors

These motors are routinely used in low to high volume production applications. Our Standard motors offer standard customizations, and come with extended customer and product support. Customizations available include motor windings for optimal performance under your specific operating conditions, various shaft customizations; and customized motor leads and connectors.

These motor are assembled at our main manufacturing facility in Northern California, where we can quickly provide a prototype (usually within one week), so you can start testing without delay.

Standard motors come with a two-year warranty, extended customer support, and extended product support. Standard motors are also available with REACH or Conflict Minerals certifications.

Quick Prototype Turnaround

Extended 2 Year Warranty

Full Product Support

Designed and Manufactured in California

Winding Options

Multiple Shaft Options

Variety of Connector and Wiring Options

Encoder Options

Available Certifications

Below is a list of our most popular windings for the 4418 Series motors:

| Model Number: | NEMA size: | Step Angle: | Connection Type: | Length in (mm): | Current AMP: | Holding Torque oz-in (Nm): | Resistance: | Inertia (oz-in^2): | Weight (lbs): | Number of Leads: |

| 4418F-01 | 17 | 1.8° | Bipolar | 1.02 (25.9) | 0.67 | 27.0 (0.19) | 7.60 | 0.14 | 0.35 | 4 |

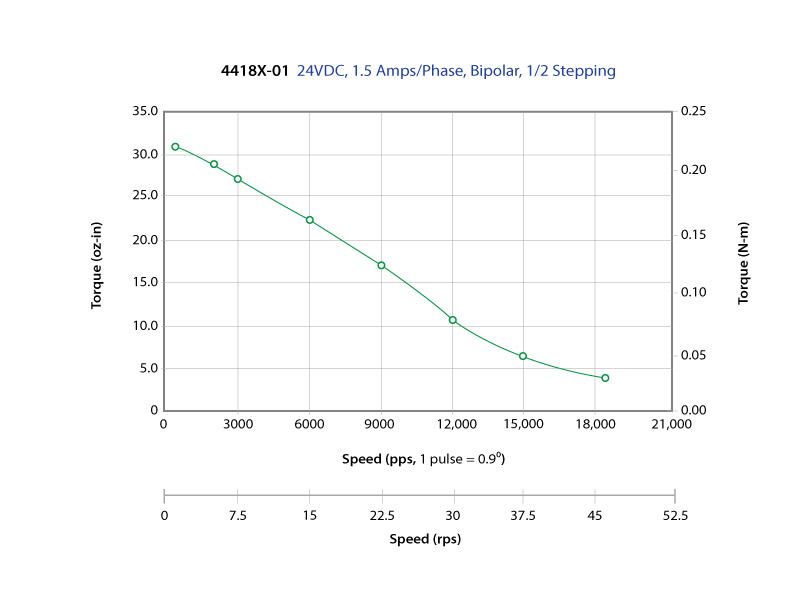

| 4418X-01 | 17 | 1.8° | Bipolar | 1.17 (29.7) | 1.50 | 37.0 (0.26) | 1.50 | 0.21 | 0.45 | 4 |

| 4418S-01 | 17 | 1.8° | Bipolar | 1.35 (34.3) | 1.70 | 61.0 (0.43) | 1.60 | 0.29 | 0.55 | 4 |

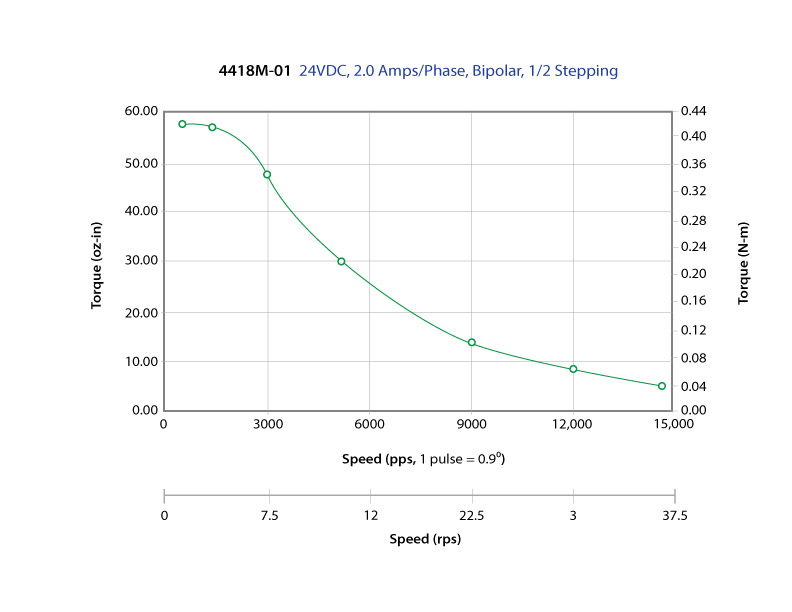

| 4418M-01 | 17 | 1.8° | Bipolar | 1.58 (40.1) | 2.00 | 71.0 (0.50) | 1.20 | 0.37 | 0.65 | 4 |

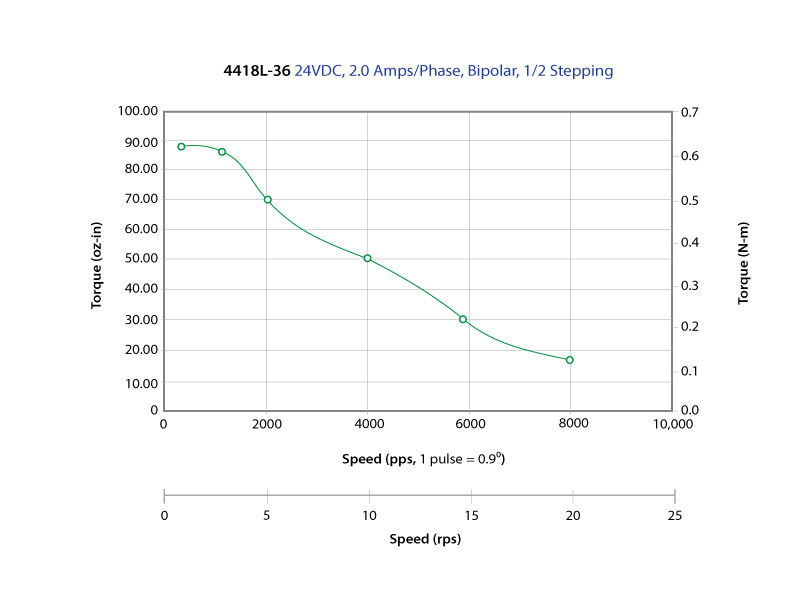

| 4418L-36 | 17 | 1.8° | Bipolar | 1.89 (48.0) | 2.00 | 100.0 (0.71) | 1.60 | 0.46 | 0.85 | 4 |

Designed for minimum 18.65W output power at 48VDC

Extended Winding Database

Not seeing exactly what you need? Our database contains hundreds of different windings. Just tell us about the requirements of your product, or simply tell us how much dynamic torque you need to achieve at what speed, and we will match you with the perfect winding.

Custom Windings

Need to dial in the performance of your product precisely? We can create a completely custom winding that will deliver the maximum performance. We can make sure that your motor delivers the dynamic torque you need at your desired operating speed with minimum resonance.

Inquire About Extended or Custom WindingStandard Motor Dimensions

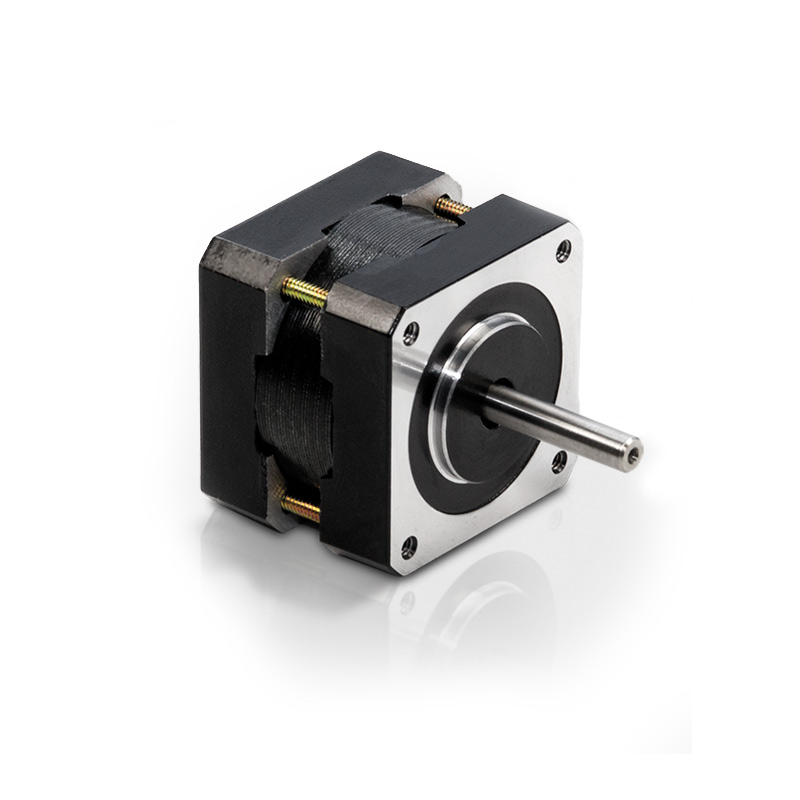

Specialty Motors

Specialty motors are designed and manufactured to operate in unique environments for specific applications. Vacuum rated motors, for example, are perfect for environments where out-gassing needs to be minimized, which includes vacuum chambers, space applications, and clean room environments.

IP (environmental protection) rated motors are perfect for applications exposed to humidity, water, oil, and other various debris.

We also carry motors that are specifically designed for medical, aerospace, automotive, and other industries with specific guidelines and requirements.

Request a Quote for a Specialty MotorIP Rated Motors

Vacuum Rated Motors

High/Low Temp Operation

Aerospace Grade

Automotive Grade

Medical Grade

OEM Motors

OEM Motors are best for high volume orders. We will works side-by-side with you and your team to design a motor that will fit the precise needs of your application. All Engineering and Support is done in-house, in our Northern California facility. Prototypes are assembled at this facility as well.

Manufacturing will take place at our High-Volume manufacturing facility in Asia, with Kanban Stocking in California.

Request a Quote for an OEM MotorDesigned from the Ground Up

Better Supply Chain Control

Frameless Motors

Integrated Components

Custom Housings

Custom Stator Designs

Custom Shaft Designs

And Much More

Web Motors

Web motors are available for online purchase and usually ship within 2-5 business days of ordering. These motors consist of our popular series and windings, and offer customizations such as single or double shaft configuration and an encoder option.

These motors are perfect for simple, one-off, projects that do not require specialized or optimized solutions. Web motors come with standard one-year warranty, and limited support.

Select Windings

Rear Shaft Option

Encoder Option

Most Orders Ship Within 2 business days

Available Online

1 Year, Limited Support Warranty

Following motors are available for online purchase:

| Model Number: | Starting Price: | NEMA size: | Step Angle: | Connection Type: | Length in (mm): | Current AMP: | Holding Torque oz-in (Nm): | Resistance: | Inertia (oz-in^2): | Weight (lbs): | Number of Leads: | |

| WO-4418F-01 | $46.79 | 17 | 1.8° | Bipolar | 1.02 (25.9) | 0.67 | 27.0 (0.19) | 7.60 | 0.14 | 0.35 | 4 | |

| WO-4418X-01 | $46.38 | 17 | 1.8° | Bipolar | 1.17 (29.7) | 1.50 | 37.0 (0.26) | 1.50 | 0.21 | 0.45 | 4 | |

| WO-4418S-01 | $45.57 | 17 | 1.8° | Bipolar | 1.35 (34.3) | 1.70 | 61.0 (0.43) | 1.60 | 0.29 | 0.55 | 4 | |

| WO-4418M-01 | $49.86 | 17 | 1.8° | Bipolar | 1.58 (40.1) | 2.00 | 71.0 (0.50) | 1.20 | 0.37 | 0.65 | 4 | |

| WO-4418L-36 | $58.46 | 17 | 1.8° | Bipolar | 1.89 (48.0) | 2.00 | 100.0 (0.71) | 1.60 | 0.46 | 0.85 | 4 |

Designed for minimum 18.65W output power at 48VDC

Web Motor Dimensions

| Model Number: | Length A (in) | Length A (mm) |

| WO-4418F-01 | 1.02 in | 25.9 mm |

| WO-4418X-01 | 1.17 in | 29.7 mm |

| WO-4418S-01 | 1.35 in | 34.3 mm |

| WO-4418M-01 | 1.58 in | 40.1 mm |

| WO-4418L-36 | 1.89 in | 48.0 mm |

Choose Series Model

Here are some of the most popular windings for this motor:

| Availability: | Model Number: | NEMA size: | Step Angle: | Connection Type: | Length in (mm): | Current AMP: | Holding Torque oz-in (Nm): | Resistance: | Inertia (oz-in^2): | Weight (lbs): | Number of Leads: |

| Buy Online | 4418F-01 | 17 | 1.8° | Bipolar | 1.02 (25.9) | 0.67 | 27.0 (0.19) | 7.60 | 0.14 | 0.35 | 4 |

| Buy Online | 4418X-01 | 17 | 1.8° | Bipolar | 1.17 (29.7) | 1.50 | 37.0 (0.26) | 1.50 | 0.21 | 0.45 | 4 |

| Buy Online | 4418S-01 | 17 | 1.8° | Bipolar | 1.35 (34.3) | 1.70 | 61.0 (0.43) | 1.60 | 0.29 | 0.55 | 4 |

| Buy Online | 4418M-01 | 17 | 1.8° | Bipolar | 1.58 (40.1) | 2.00 | 71.0 (0.50) | 1.20 | 0.37 | 0.65 | 4 |

| Buy Online | 4418L-36 | 17 | 1.8° | Bipolar | 1.89 (48.0) | 2.00 | 100.0 (0.71) | 1.60 | 0.46 | 0.85 | 4 |

Not seeing exactly what you need?

We can customize your motor's winding to maximize the torque at your desired operating speed (within the constraints of power input and motor size). You get this completely free of charge.

Just tell us what you need:

Here's What I NeedStepper Motors

-

4018 Series

Features & Benefits

Features & Benefits- Slim, Compact Design

- Cost Effective

- Up to 42 oz-in (0.30 N-m) Holding Torque

-

4118 Series High Torque Stepper Motor

Features & Benefits

Features & Benefits- More torque than standard NEMA 17 stepper motors

- Custom wound for high speed or low speed applications

- Up to 115 oz-in (0.81 N-m) Holding Torque

-

4118 Series + Integrated Connector High Torque Stepper Motor Stepper with Integrated Connector

Features & Benefits

Features & Benefits- More torque than standard NEMA 17 stepper motors

- Custom wound for high speed or low speed applications

- Up to 115 oz-in (0.81 N-m) Holding Torque

Get Exactly What You Need

In motion control, no two designs are the same. When you’re optimizing for the best efficiency, accuracy, or speed, you don’t want a motor that is close enough, you want a motor that will meets your requirements precisely. This is exactly what we can provide: a motor with the exact specifications you need for your specific design or application.

On Demand Assembly

Our unique method of assembly allows us to stock a large selection of standard components that can be assembled in a multitude of ways for your specific needs. This allows us to assemble a motor that meets your exact specifications, with minimal lead time, and at a great price point.

Tell Us About Your Application.

Fill out the form below and one of our specialists will study your applications and match you with a product that will fit your exact needs.

Custom Components & Custom Motors

In situations where a more custom solution is required, we can modify many components to meet your exact specifications. Our in-house machine shop can produce custom components such as housings and shafts, while our wiring department can create custom wire harnesses for specific applications. By combining custom components with our On-Demand assembly process, you’ll get a customized motor at a lower cost, and at faster lead time than what’s available from most traditional manufacturers.

Great Price

Whether you choose Lin Engineering’s ready-to-ship product, or our On-Demand product, or a customized solution, the end result is that you get exactly what you need, at a fantastic price point, with minimal lead time.

Here are few more benefits you’ll enjoy while working with us:

LIN PRODUCTS ARE:

Accurate

Our stepper motors consistently outperform competitive products in accuracy—by at least 2x that of industry standards.

Consistent

Every motor shipped is inspected beforehand to ensure your motor performs as specified. You benefit from consistent performance from your application.

Reliable

The quality of every component that goes into each Lin Engineering stepper motor as well as every step of the manufacturing process is tightly scrutinized and managed to the highest standards. We follow lean manufacturing practices and even developed our own 4.5 Sigma Way quality assurance system. We guarantee that our product will meet or exceed your needs and greatly reduce the potential for costly RMA’s.

Innovative

We’ve received many patents related to stepper motor technology. We’ve even reinvented a stepper motor from the ground up—check out our Z-Series motor for the smoothest, quietest, and most accurate motion available.

Meet Requirements

We manufacture and keep data with accordance to ISO9001:2008, AS9100C and many other standards. For this reason, our motors can be found in numerous FDA and FAA-approved applications.

SERVICES

Customization

We can customize windings to ensure maximum torque and performance at a desired speed as well as customize the connections, shaft, housing, and add an encoder. Our motors are designed to fit your application, not the other way around.

Small And Large Quantity Manufacturing

Our unique On-Demand manufacturing process is optimized for speed and efficiency, allowing us to make just a few units or as many as thousands of units at a time.

Learn More About Our Capabilities

Rapid Prototyping

We can provide working prototypes quickly, which allows you to begin critical testing of the application right away so that getting the product to market happens as fast as possible.

Learn More About Rapid Prototyping

SUPPORT

Ongoing Product Support

Once a customer, always a customer—Lin Engineering products are fully warranted and our experts are standing by to support you and your application whenever you need us.

Expert Knowledge

There’s no better source of information than from the people who designed and manufactured your product. If you have a question, we are available.

Application Specialists

Our team of applications specialists deal with issues just like yours every day in and day out. Tell us your requirements and we’ll match you with a product that will precisely fit your requirements.

Tell Us About Your Application.

Fill out the form below and one of our specialists will study your applications and match you with a product that will fit your exact needs.

Get up to 35% more torque versus a standard motor of the same size.

4418 Series NEMA 17 size stepper motors provide great length to torque ratio. This motor is perfect for applications with limited space, which require more torque than what a standard motor can provide. The 4418 delivers up to 35% more torque than a standard stepper motor of the same length.

How did we do it?

The design of the 4418 Series stepper motor is similar to our 4118 Series motor. It utilizes an 8-pole stator to maximize the torque output. However, the difference is in our patented low profile end cap (end bell) with an integrated bearing. This low profile end cap allows us to use a larger rotor, with larger magnetic surface, which produces more torque, while retaining short motor length.

Application Examples:

- CNC systems

- 3D printer

- Imaging Devices

- Optical Devices

- Medical applications

- High load linear applications

- Compact robotics

- Any application requiring a NEMA 17 size short stack length motor, with higher torque loads.

Popular Applications for this motors include:

High speed, data analysis lab equipment (Shakers and mixers)

| MODEL | 4418S-19D-02 |

| Hi speed, Data analysis lab equipment (Shakers, Mixers) | |

|

|

| MODEL | 4418L-36D-02RO |

| Medical machine designed to test for infectious diseases | |

|

|

| MODEL | 4418L-36-RO, 4418M-04P-RO |

| Aiming large antennas | |

|

|

Need even more torque?

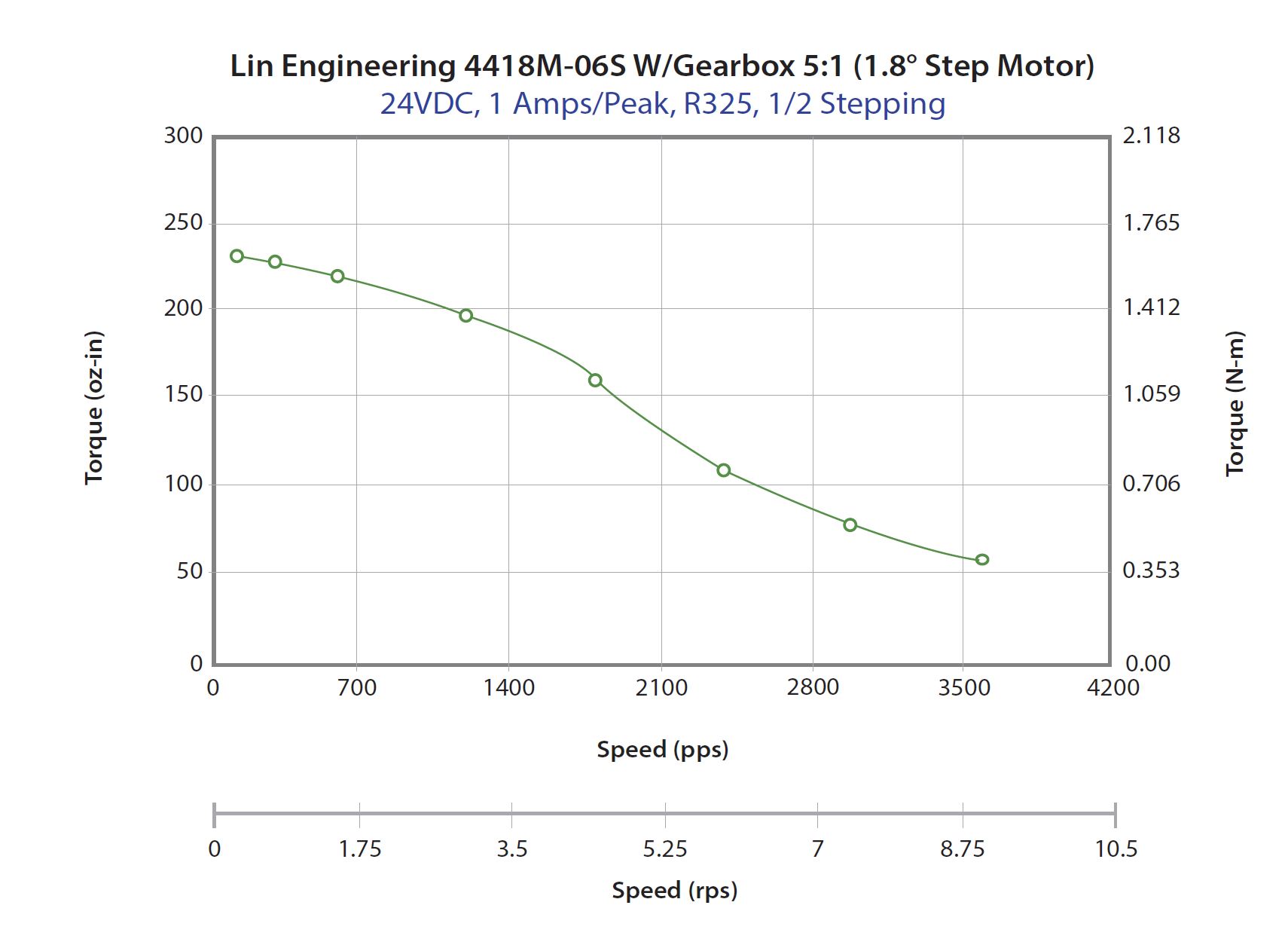

When you combine the 4418 Series motor with our low profile Slim planetary gearbox, you’ll get even more torque from a very compact package. This is perfect for applications with small and tight space constraints.

The below torque curve demonstrates output torque of a 4418M-06S, combined with our Slim planetary gearbox. Total frame length is 2.1”